Pioneering cooling solutions for a more sustainable future.

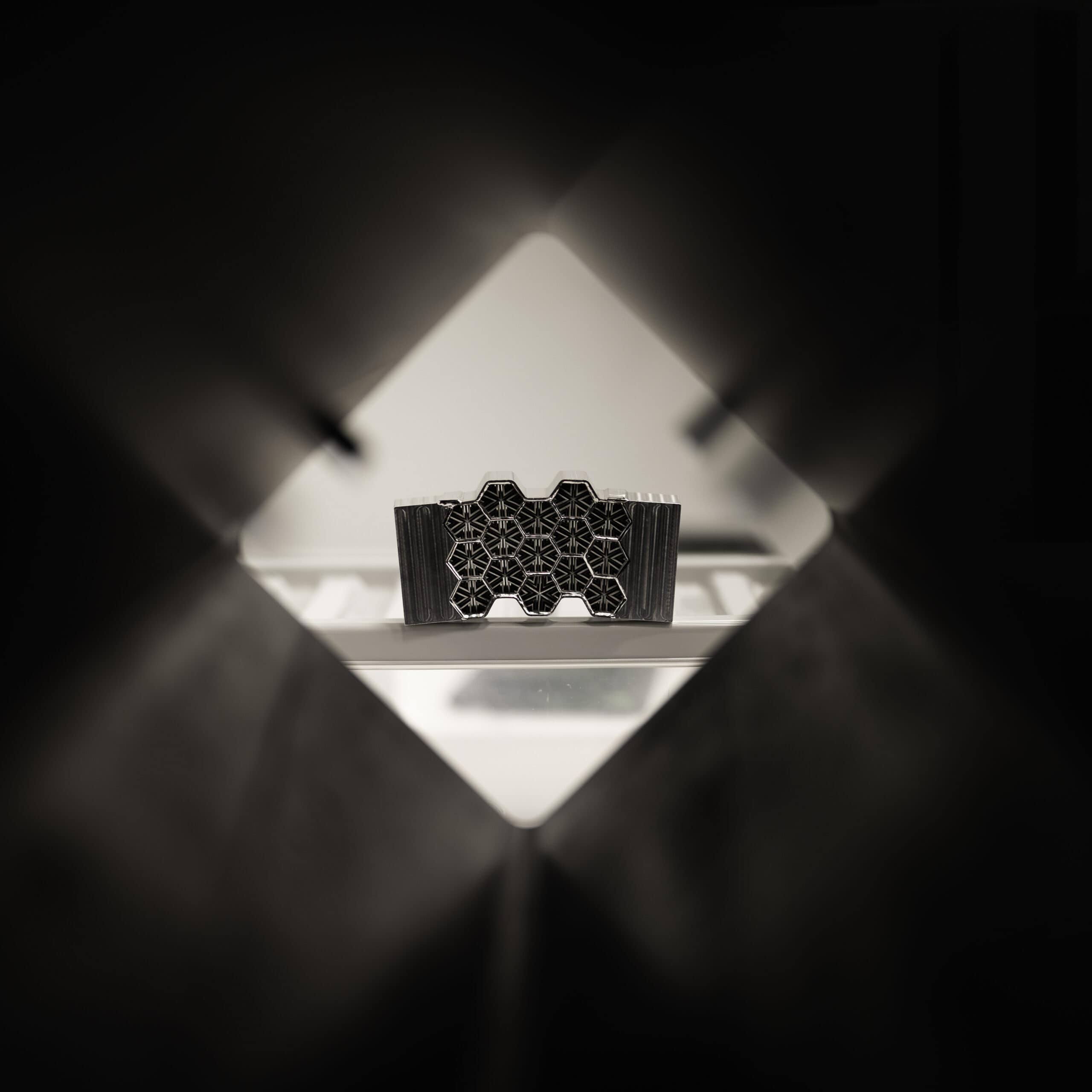

Heat Exchangers

Qdot designs and manufactures advanced heat exchangers tailored to the most demanding applications.

By combining binder-jet additive manufacturing with world-leading aerothermal design, Qdot delivers lightweight, high-performance heat exchangers that unlock new possibilities across aerospace, defence, energy, and industrial markets.

Our approach allows us to build bespoke solutions to fit complex installation volumes with rapid iterations so customers can test, refine, and deploy solutions faster than ever.

- Radiators with up to 20% less drag

- Robust oil coolers

- Water cooled charge air coolers

- Cryogenic heat exchangers

- Exhaust heat exchangers with low back pressure

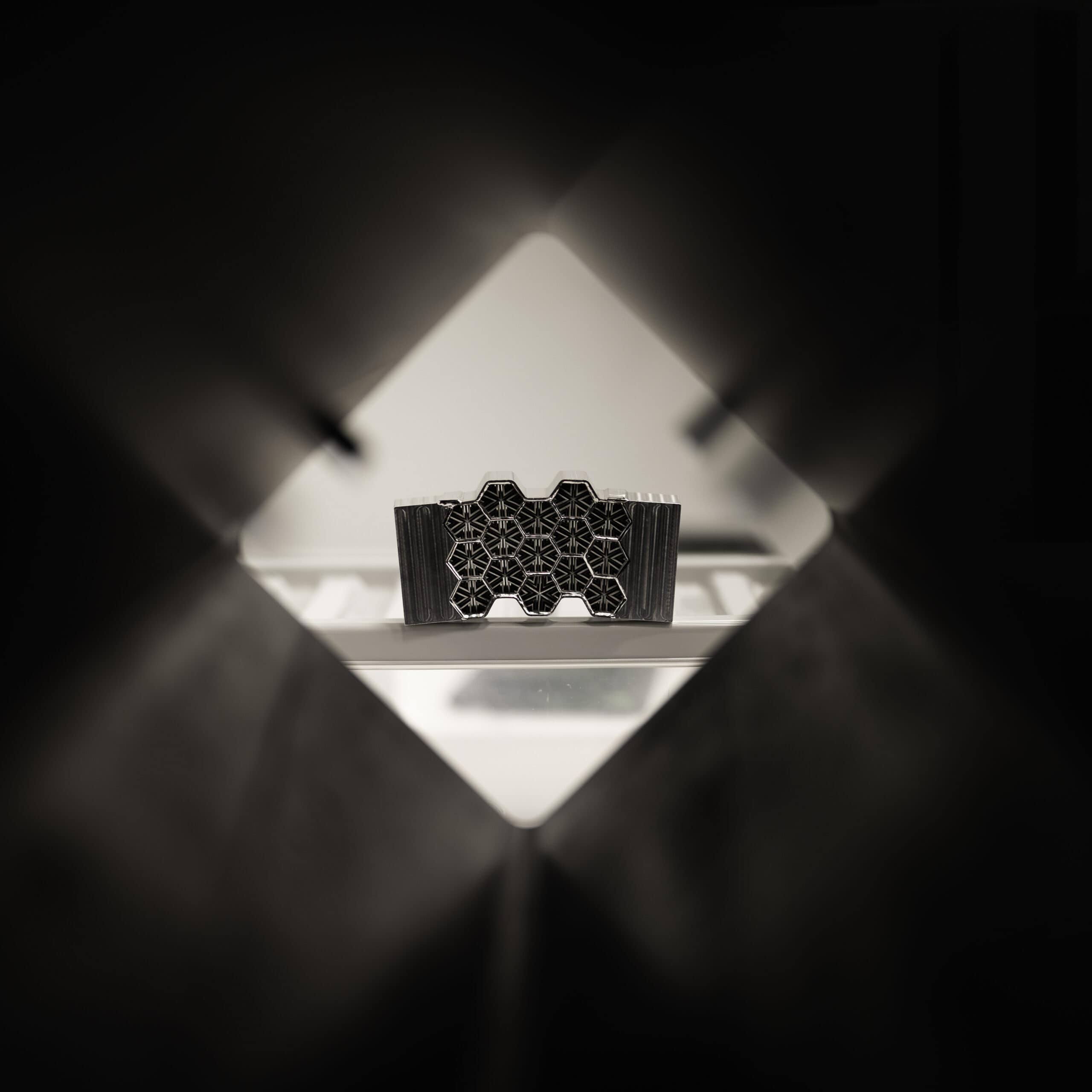

Heat Exchangers

Qdot designs and manufactures advanced heat exchangers tailored to the most demanding applications.

By combining binder-jet additive manufacturing with world-leading aerothermal design, Qdot delivers lightweight, high-performance heat exchangers that unlock new possibilities across aerospace, defence, energy, and industrial markets.

Our approach allows us to build bespoke solutions to fit complex installation volumes with rapid iterations so customers can test, refine, and deploy solutions faster than ever.

- Radiators with up to 20% less drag

- Robust oil coolers

- Water cooled charge air coolers

- Cryogenic heat exchangers

- Exhaust heat exchangers with low back pressure

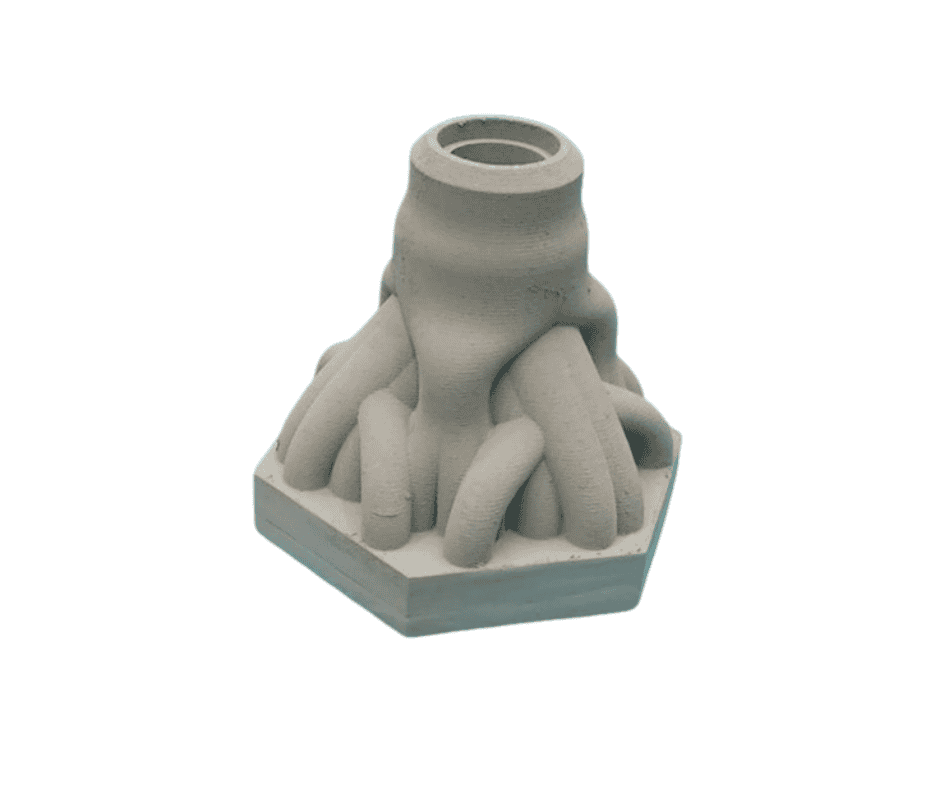

Heat Sinks

Qdot’s proprietary heat sink technology is engineered to manage tomorrow’s elevated heat fluxes in power electronics, data centres, and fusion reactor diverters.

The technology originated from research led by our co-founder, Jack Nicholas, at the Oxford University Thermofluids Laboratory, and has been further developed through collaborative projects with Tokamak Energy.

Designed to support next-generation computing, power systems, and fusion applications, these heat sinks enable reliable performance at extreme thermal loads while improving the sustainability of cooling in sectors such as data centres and clean energy.

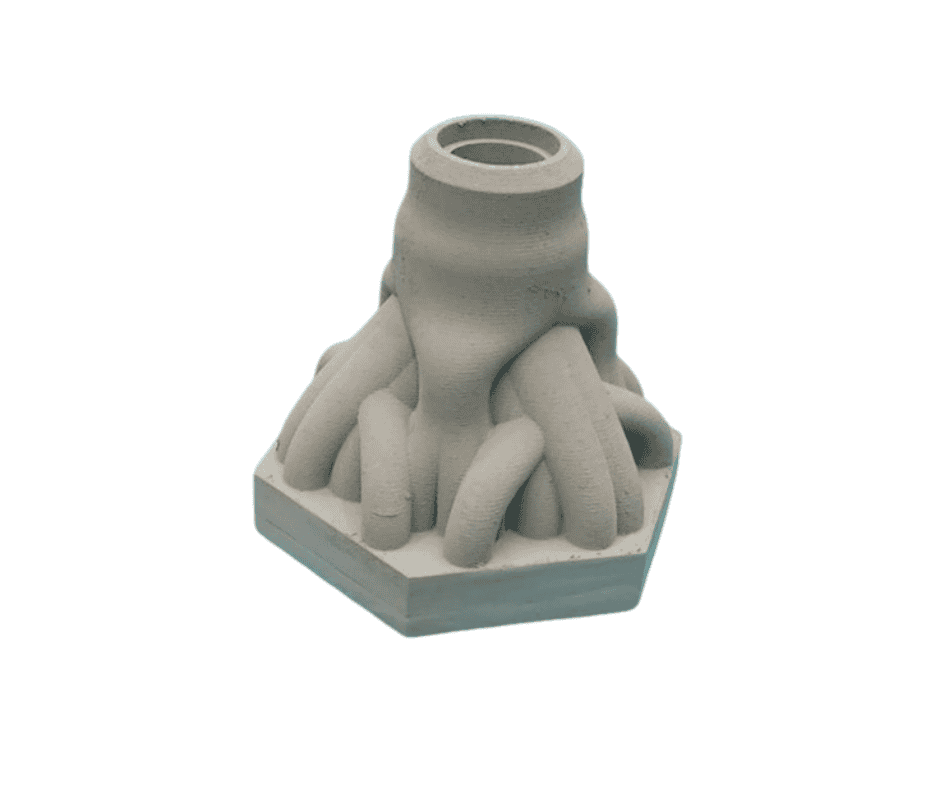

Heat Sinks

Qdot’s proprietary heat sink technology is engineered to manage tomorrow’s elevated heat fluxes in power electronics, data centres, and fusion reactor diverters.

The technology originated from research led by our co-founder, Jack Nicholas, at the Oxford University Thermofluids Laboratory, and has been further developed through collaborative projects with Tokamak Energy.

Designed to support next-generation computing, power systems, and fusion applications, these heat sinks enable reliable performance at extreme thermal loads while improving the sustainability of cooling in sectors such as data centres and clean energy.

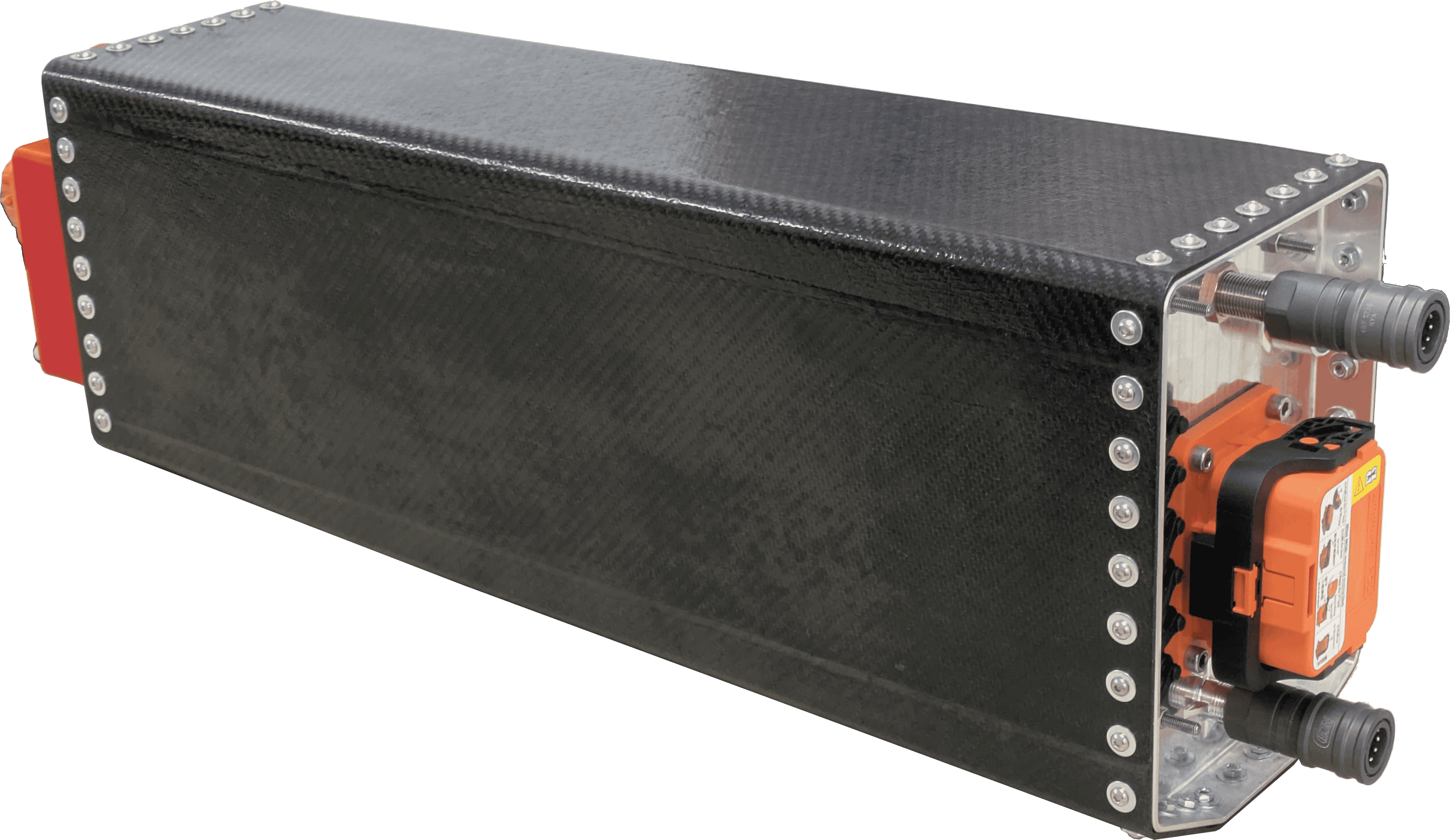

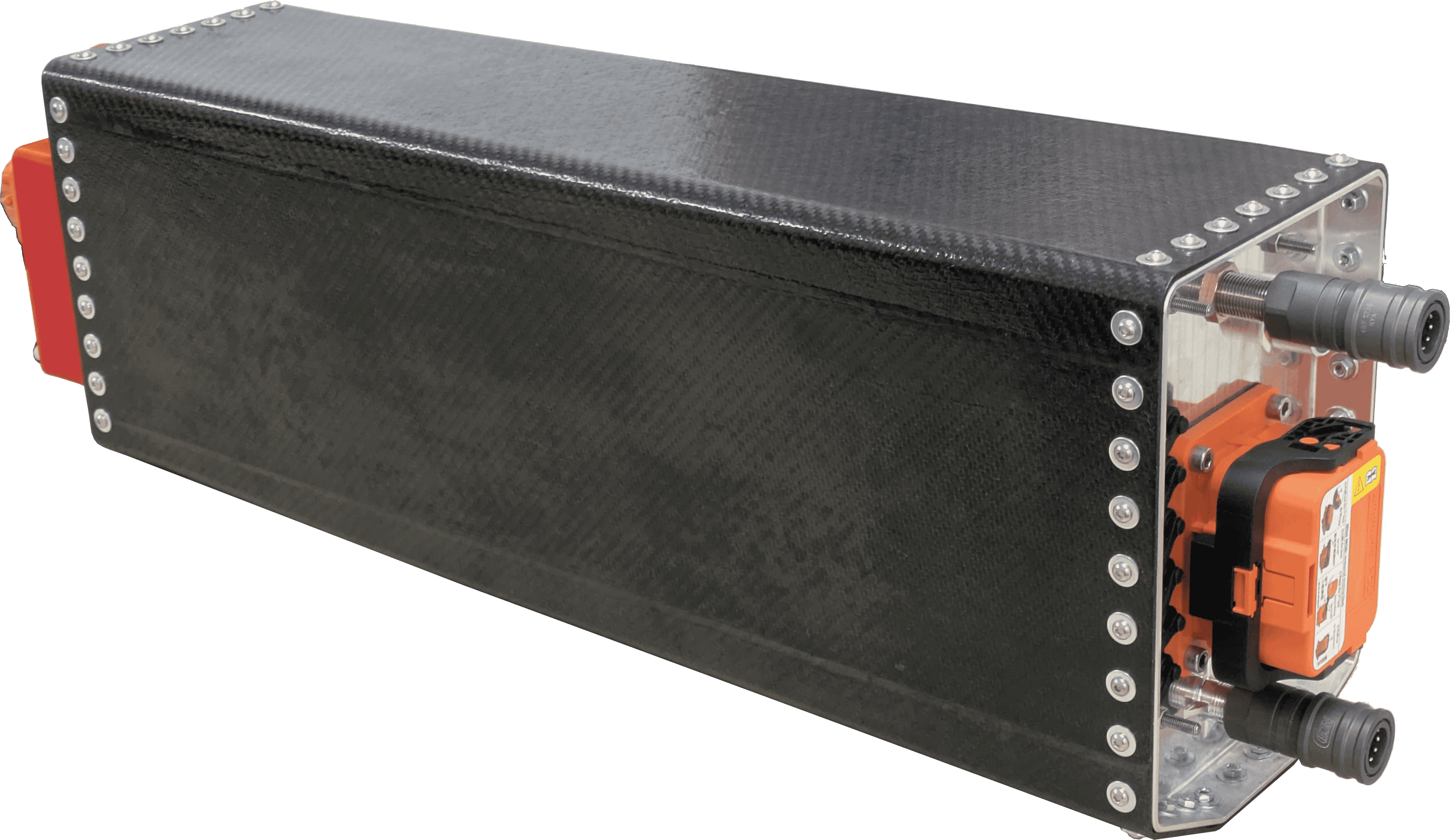

Battery Cooling

Our expertise covers high-performance heat exchangers, heat sinks for extreme heat flux applications, turbomachinery such as compressors and turbines for fuel cell systems, and high-power battery packs for hybrid platforms.

Battery Cooling

Our expertise covers high-performance heat exchangers, heat sinks for extreme heat flux applications, turbomachinery such as compressors and turbines for fuel cell systems, and high-power battery packs for hybrid platforms.

Fuel Cell Propulsion

Qdot provides end-to-end design and integration capabilities for fuel cell propulsion, combining deep aerothermal expertise with advanced cooling technologies. We specialise in optimising the balance of plant and cooling system.

Our multidisciplinary approach ensures that each subsystem is not only efficient in isolation, but works seamlessly as part of a lightweight, reliable, and certifiable propulsion system.

By delivering bespoke designs and rapid prototyping, Qdot helps customers accelerate the development of hydrogen-powered aircraft, drones, and vehicles that demand both high performance and zero-emission operation.

Fuel Cell Propulsion

Qdot provides end-to-end design and integration capabilities for fuel cell propulsion, combining deep aerothermal expertise with advanced cooling technologies. We specialise in optimising the balance of plant and cooling system.

Our multidisciplinary approach ensures that each subsystem is not only efficient in isolation, but works seamlessly as part of a lightweight, reliable, and certifiable propulsion system.

By delivering bespoke designs and rapid prototyping, Qdot helps customers accelerate the development of hydrogen-powered aircraft, drones, and vehicles that demand both high performance and zero-emission operation.

Turbomachinery

Qdot’s next-generation 2-stage turbocharger is purpose-built for aviation fuel cell systems, unlocking higher stack pressures with minimal parasitic power losses.

Paired with our high-power-density battery packs, this integrated solution delivers lighter, more efficient propulsion architectures, cutting overall system mass by up to 10%, enabling cleaner, more capable, and longer-range electric flight.

Turbomachinery

Qdot’s next-generation 2-stage turbocharger is purpose-built for aviation fuel cell systems, unlocking higher stack pressures with minimal parasitic power losses.

Paired with our high-power-density battery packs, this integrated solution delivers lighter, more efficient propulsion architectures, cutting overall system mass by up to 10%, enabling cleaner, more capable, and longer-range electric flight.