Pioneering cooling solutions for a more sustainable future.

What we do

Underpinned by our cutting-edge aerothermal and systems engineering expertise and next-generation proprietary technology, we offer better performance, lower cost and more responsive delivery for our customers.

Our expertise covers high-performance heat exchangers, heat sinks for extreme heat flux applications, turbomachinery such as compressors and turbines for fuel cell systems, and high-power battery packs for hybrid platforms.

What we do

Underpinned by our cutting-edge aerothermal and systems engineering expertise and next-generation proprietary technology, we offer better performance, lower cost and more responsive delivery for our customers.

Our expertise covers high-performance heat exchangers, heat sinks for extreme heat flux applications, turbomachinery such as compressors and turbines for fuel cell systems, and high-power battery packs for hybrid platforms.

Our capabilities

Qdot offers a unique end-to-end capability spanning design, manufacture, and test of advanced thermal and propulsion technologies.

Alongside component-level excellence, we also provide system-level design and integration for complete fuel cell propulsion systems, ensuring seamless performance across stacks, balance of plant, and power electronics.

Our high-performance thermal management solutions are enabled by our proprietary binder-jet sintering additive manufacturing capability. Compared to conventional laser-sintered AM, binder jetting delivers greater flexibility, lower cost, and more scalability, enabling us to produce complex geometries, tailored performance, and rapid prototypes that accelerate innovation for our customers.

Our capabilities

Qdot offers a unique end-to-end capability spanning design, manufacture, and test of advanced thermal and propulsion technologies.

Alongside component-level excellence, we also provide system-level design and integration for complete fuel cell propulsion systems, ensuring seamless performance across stacks, balance of plant, and power electronics.

Our high-performance thermal management solutions are enabled by our proprietary binder-jet sintering additive manufacturing capability. Compared to conventional laser-sintered AM, binder jetting delivers greater flexibility, lower cost, and more scalability, enabling us to produce complex geometries, tailored performance, and rapid prototypes that accelerate innovation for our customers.

Case Studies.

Honeywell STRATA Project

Qdot Technology is partnering with Honeywell, Oxford Thermofluids Institute, 3T Additive Manufacturing Ltd and BeyondMath on a £14.1m program to develop the next generation of Environmental Control Systems (ECS) and Cabin Pressure Control Systems (CPCS) for commercial aircraft.

This is a testament to Qdot’s aerothermal design expertise and novel additive manufacturing methods.

Honeywell STRATA Project

Qdot Technology is partnering with Honeywell, Oxford Thermofluids Institute, 3T Additive Manufacturing Ltd and BeyondMath on a £14.1m program to develop the next generation of Environmental Control Systems (ECS) and Cabin Pressure Control Systems (CPCS) for commercial aircraft.

This is a testament to Qdot’s aerothermal design expertise and novel additive manufacturing methods.

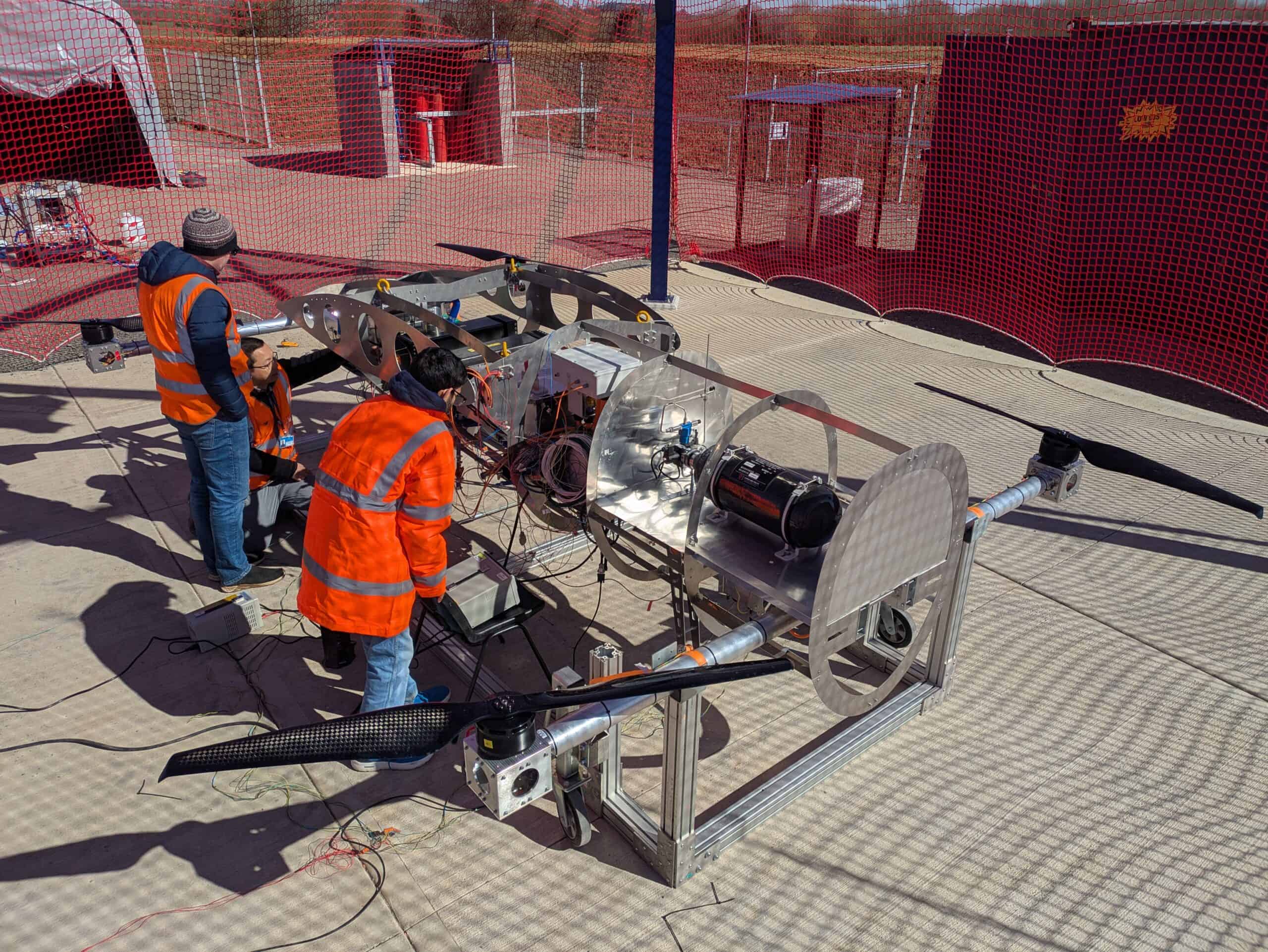

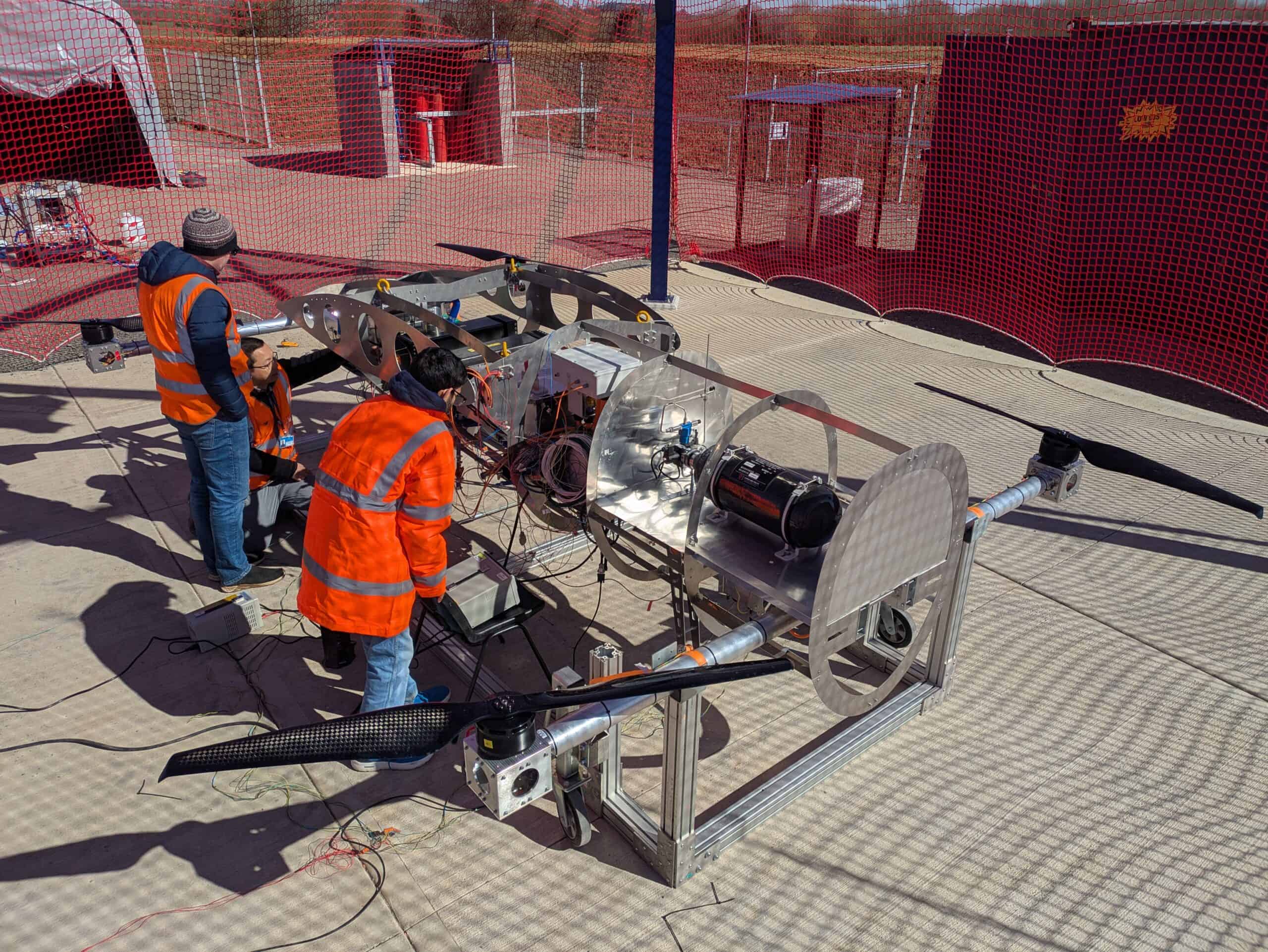

Long Range Drone

By combining innovative thermal management and light weight fuel cell system design with a hybrid architecture, Qdot enabled a hydrogen-powered drone platform with a 400km range and 100kg payload.

The architecture provides extended fuel cell life and delivers 20% lower cost of ownership.

Long Range Drone

By combining innovative thermal management and light weight fuel cell system design with a hybrid architecture, Qdot enabled a hydrogen-powered drone platform with a 400km range and 100kg payload.

The architecture provides extended fuel cell life and delivers 20% lower cost of ownership.

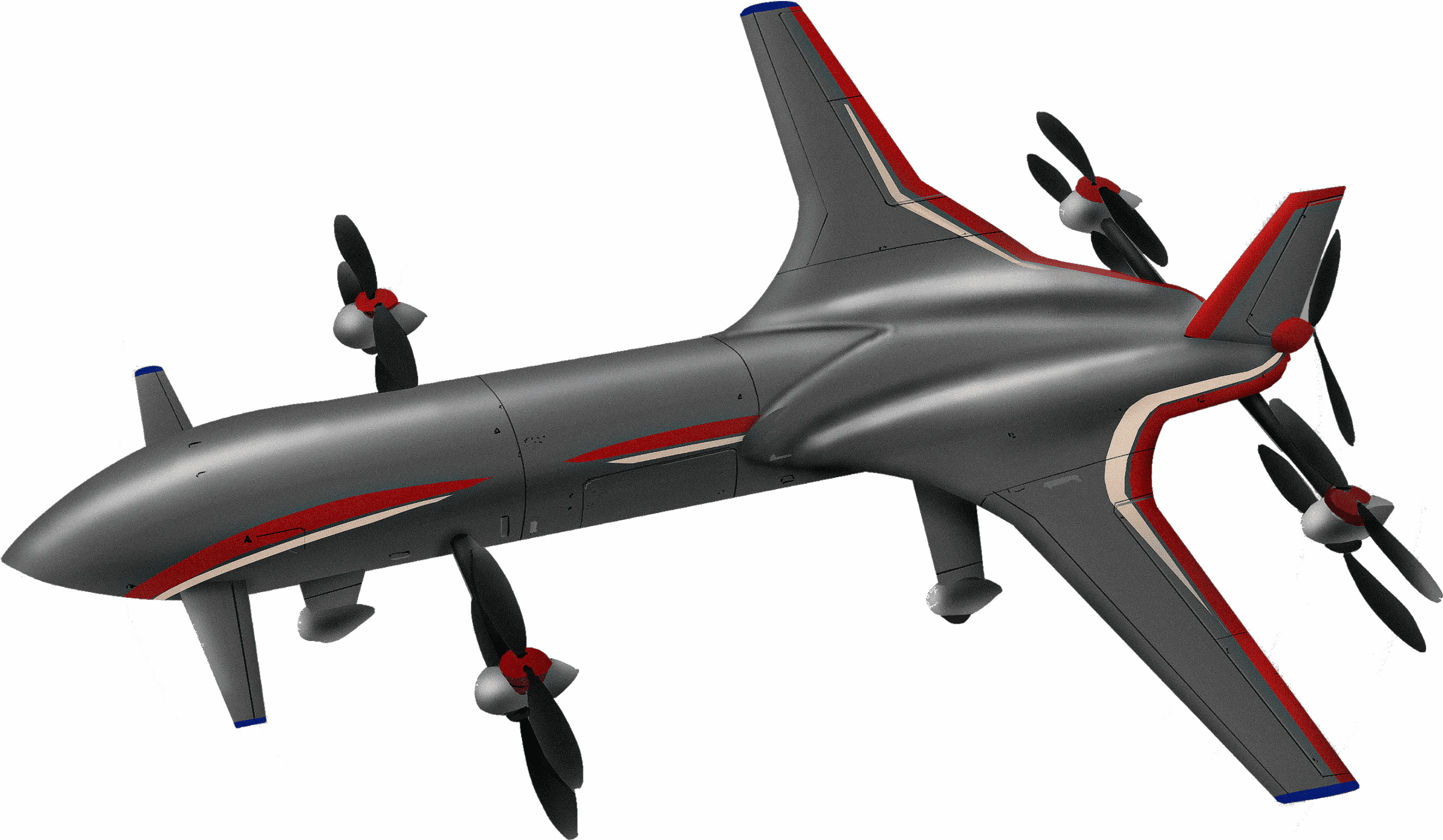

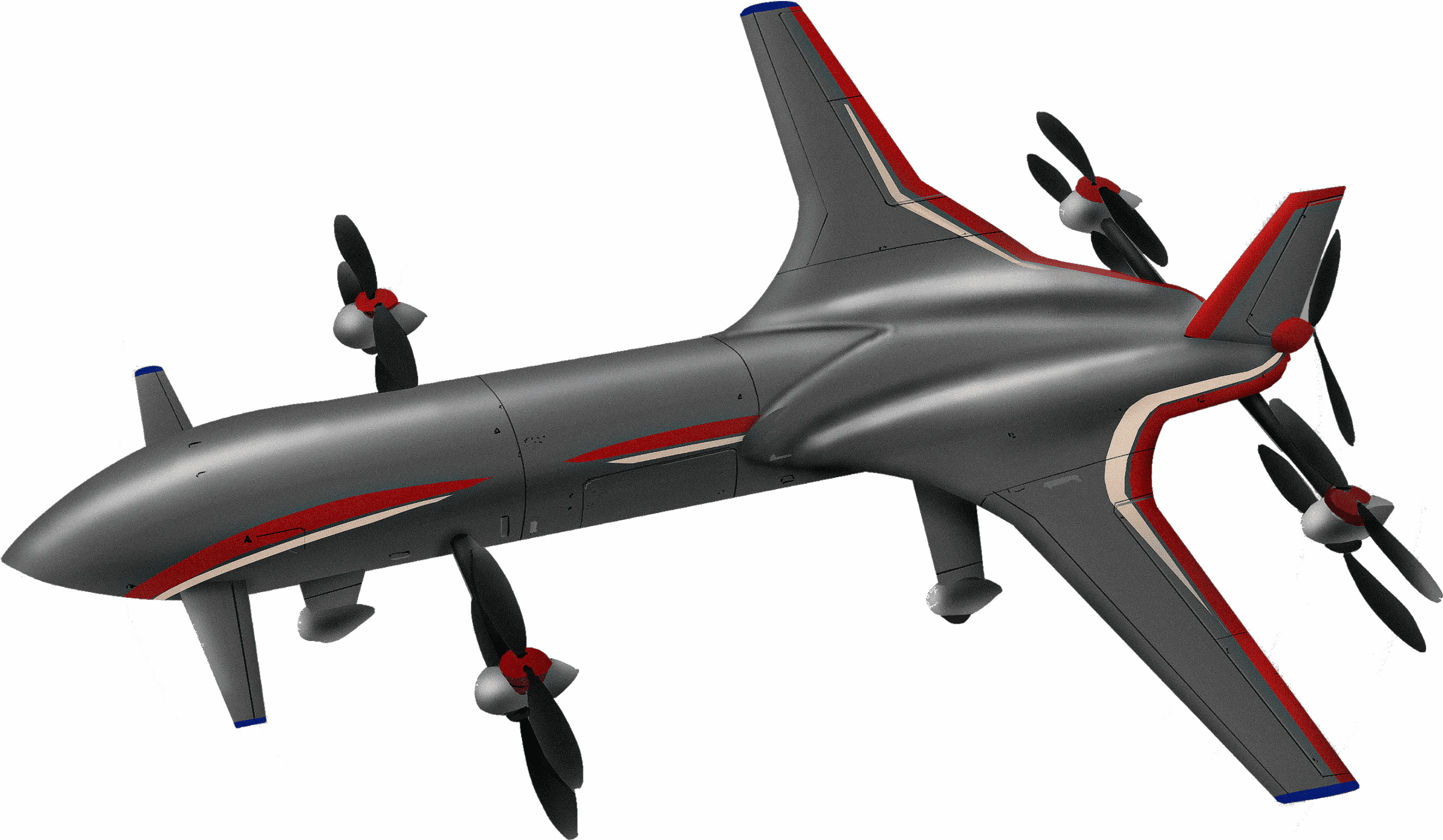

Regional Aircraft

Our system-level design and optimisation of fuel cell propulsion, thermal management and hybridisation predicts potential lifetime savings of over £90 million per aircraft.

Regional Aircraft

Our system-level design and optimisation of fuel cell propulsion, thermal management and hybridisation predicts potential lifetime savings of over £90 million per aircraft.

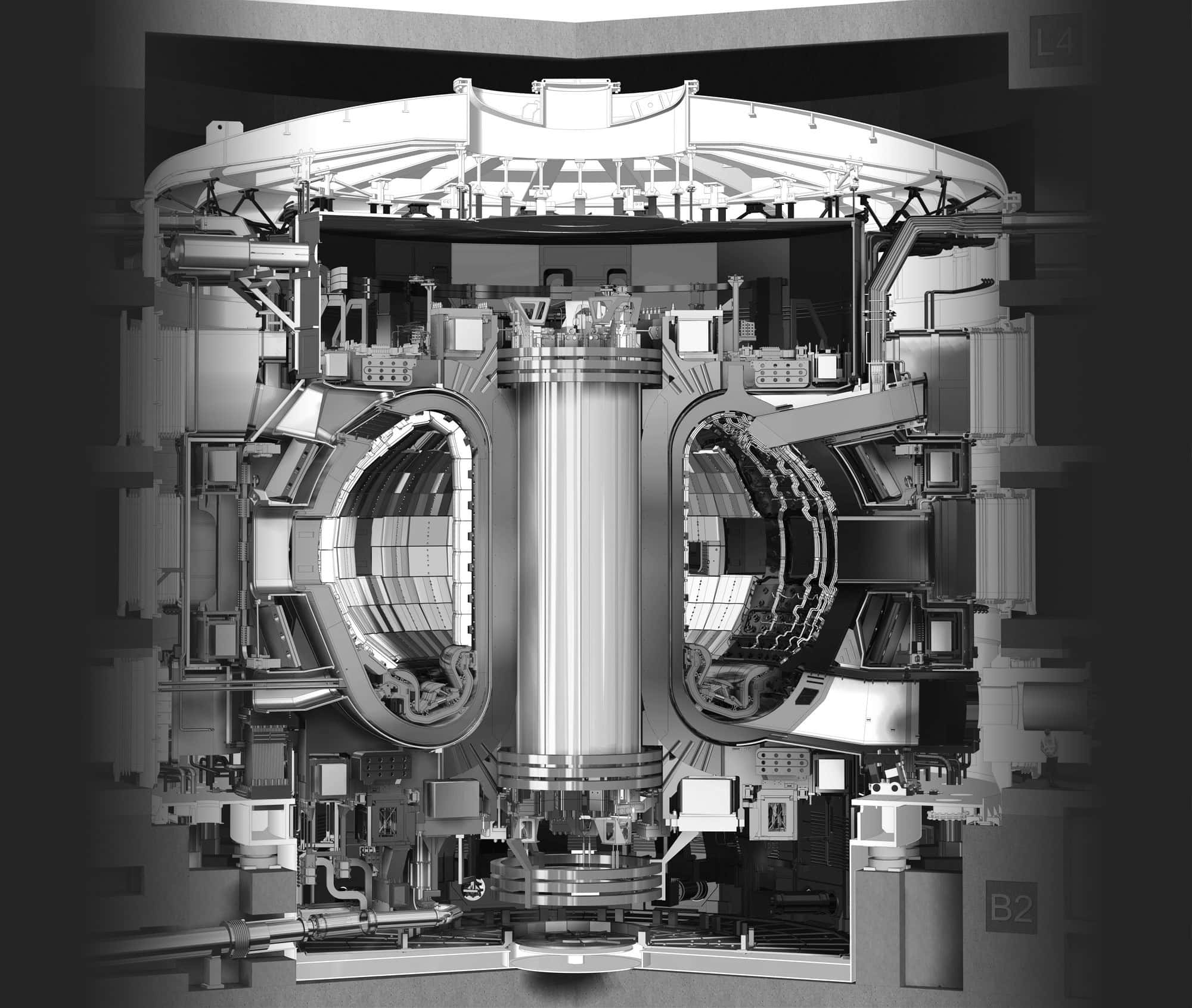

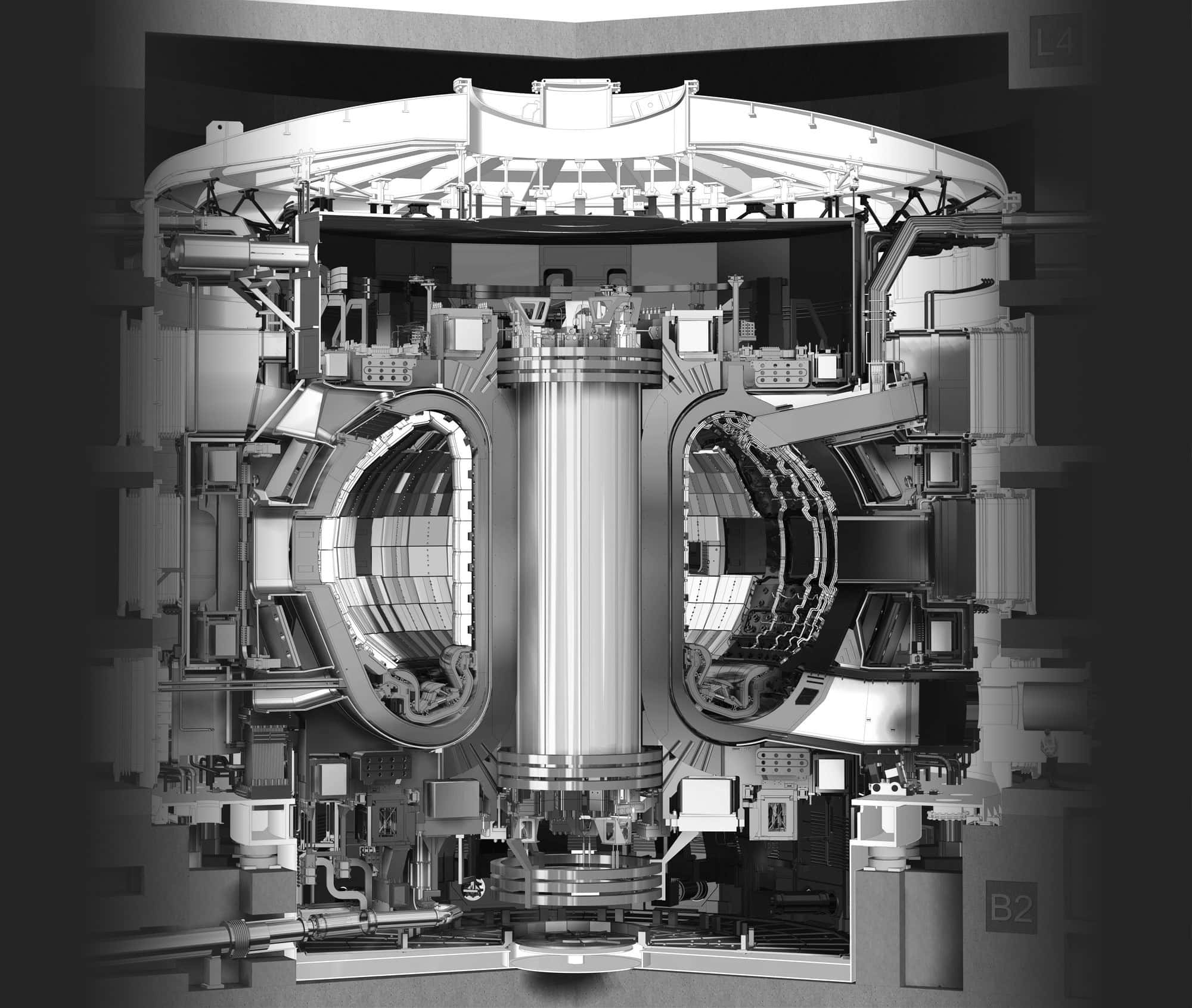

Tokamak Energy

Building on research from Oxford University’s Thermofluids Lab, Qdot collaborated with Tokamak Energy to advance fusion reactor diverter cooling technology, capable of handling the extreme heat fluxes found in nuclear fusion environments.

Tokamak Energy

Building on research from Oxford University’s Thermofluids Lab, Qdot collaborated with Tokamak Energy to advance fusion reactor diverter cooling technology, capable of handling the extreme heat fluxes found in nuclear fusion environments.